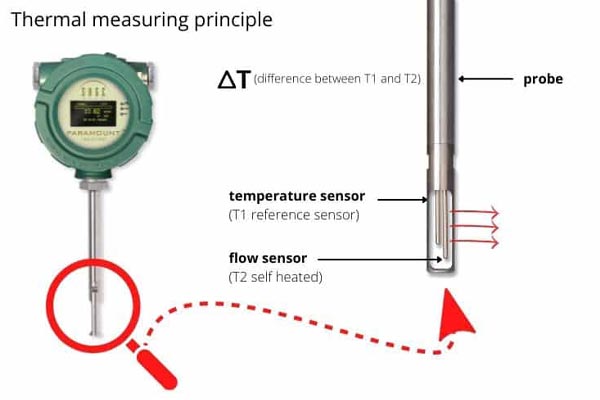

Thermal mass flow meters work on the principle of hot-wire anemometry. Instead of relying on fluid momentum, they use the heat-conducting properties of fluids to measure mass flow. A heated probe is inserted into the pipeline, and as the fluid passes, it absorbs heat. The amount of heat absorbed is directly proportional to the mass flow rate of the fluid.

These meters are available in two types: Insertion type, where a probe with sensing elements is inserted into pipes of any size, offering economical installation; and Inline type, where the flow meter becomes part of the pipeline via flanged or threaded connections, ideal for smaller diameter pipes. Their ability to measure with precision even in challenging environments makes them a reliable choice for gas flow applications.

Flow calculation formula

The mass flow rate is calculated using the formula:

m = K × (H / ΔT)^1.67

Where:

-

m = Mass flow rate

-

K = Proportionality constant

-

H = Heat loss

-

ΔT = Temperature difference between heated and reference sensors

This equation represents how heat absorbed by the flowing gas molecules relates directly to the number of molecules passing the sensor.

Two measurement methods

1. Constant Temperature Difference

In this method, a predefined ΔT is maintained between the heated velocity sensor and the reference temperature sensor. Power to the heater is adjusted to sustain this difference. At higher flow rates, more power is required, while lower flow rates need less. This approach ensures high sensitivity at low flow and excellent turndown ratios.

2. Constant Power

Here, constant power is supplied to the heated sensor. As mass flow increases, the temperature difference between the heated and reference sensors decreases. At lower flow rates, a larger temperature change occurs, allowing for great low-flow detection accuracy.