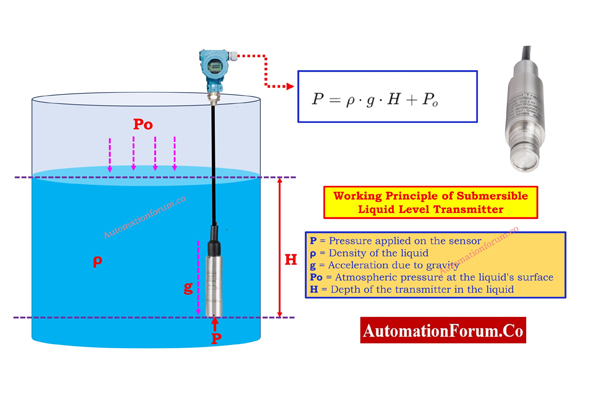

In the world of big factories and busy plants, knowing exactly how much liquid is in a tank is very important. This is where level transmitters come in. These are smart instruments that measure the height of a liquid and send that information to a computer screen.

Performance and reliability matter because if a measurement is wrong, a tank might overflow or a machine might break. Choosing a trusted manufacturer and supplier is the first step to success. You need a partner who understands how these tools are built and how they will work when they reach your site.

Who We Are as a Level Transmitter Manufacturer

As a manufacturer, we take full responsibility for every part of the instrument. Being a manufacturer is different from just being a shop. We design the product, we choose the parts, and we build it from the ground up.

Our in-house design and production mean we control the quality. We don’t guess; we test. This focus on reliability ensures that every transmitter leaving our factory is built with consistency. When you buy directly from a manufacturer, you are getting a product built with a sense of duty and pride.

Designing Level Transmitters for Industrial Needs

We don’t just build instruments in a quiet room; we design them for the “real world.” Industrial sites can be hot, dusty, or full of strong chemicals. Here is how we design for those conditions:

- Accuracy: We ensure the sensors can detect even tiny changes in liquid levels.

- Durability: We use strong materials like stainless steel that won’t rust or break easily.

- Safety: Our designs focus on protecting workers and preventing leaks in the factory.

- Ease of Use: We make the screens easy to read and the buttons simple to push so that any operator can use them.

Manufacturing Process: Built with Care

Building a level transmitter is a journey of many small, careful steps. We follow a strict path to ensure the final product is perfect:

- Material Selection: we start by picking the best raw materials that can handle heat and pressure.

- Assembly: Our skilled team puts the delicate electronics and sensors together in a clean environment.

- Quality Checks: At every step, we stop and check if the parts are fitting correctly.

- Final Inspection: Before a transmitter is boxed up, it gets one last look to make sure it looks and works like new.

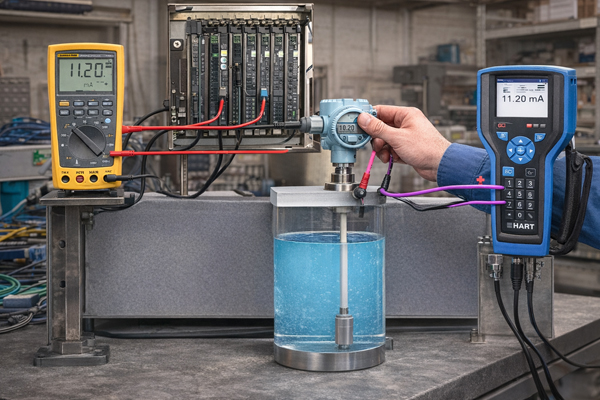

Quality Testing Before Supply

Testing is the most important part of our job as a supplier. We never supply an instrument without making sure it is ready for the field. We perform many checks, such as:

Pressure Tests

To make sure the transmitter won’t leak under heavy loads./p>

Calibration

To ensure the measurement on the screen matches the actual liquid level.

Electronic Testing

To check that the signal travels correctly to the control room.

As a reliable supplier, our responsibility is to make sure your work doesn’t stop because of a faulty tool.

From Factory to Field: Ready for Real-World Use

Once our level transmitters leave the factory, they go to work in many different industries. They are built to perform in places like:

- Water & Wastewater: Measuring clean water for cities or dirty water in treatment plants.

- Chemical: Handling liquids that would damage regular sensors.

- Pharma: Working in clean rooms where medicines are made.

- Food & Beverage: Keeping track of milk, juice, or oil while staying hygienic.

Why Performance Matters in Level Transmitters

High performance isn’t just a fancy word; it has real benefits for your business:

- Accurate Level Measurement: You always know exactly how much stock you have.

- Reduced Downtime: Reliable tools don’t break often, so your factory keeps running.

- Long Service Life: A well-built transmitter lasts for years, saving you money on replacements.

- Smooth Plant Operations: When the instruments work perfectly, the whole plant stays in balance.

Supplier Support & Delivery Across India

We are proud of our capability to supply high-quality instruments across all of India. Being a good supplier means more than just shipping a box. We provide:

Key Benefits of Choosing a Manufacturer-Supplier

When the person who makes the product is also the one who supplies it, you get big advantages:

- Direct Quality Control: No middleman means better quality.

- Faster Customization: If you need a special length or material, we can build it for you.

- Better Technical Support: We know our products inside and out because we built them.

- Reliable Supply Chain: You can trust that we will always have the parts and products you need.

Frequently Asked Questions (FAQs)

A good manufacturer controls the whole process, from design and material selection to final testing and support.

Performance ensures accuracy and reliability. Without it, you risk spills, machine damage, or incorrect inventory counts.

Yes, because the manufacturer understands the technical details and provides direct quality checks before the product reaches you.

Yes, as a manufacturer, we can adjust the size, materials, and settings to fit your specific industrial needs.

Yes, a reliable supplier provides guidance on installation, calibration, and troubleshooting.

Our transmitters are specifically designed with strong materials to handle heat, chemicals, and high pressure.

The journey of a level transmitter from our factory to your field is one of care, precision, and testing. By focusing on high-quality manufacturing and honest supply, we ensure that our instruments perform every single day. Choosing a trusted manufacturer-supplier partner ensures that your industrial measurements are accurate, your workers are safe, and your business stays productive for years to come.

If you are looking for top-quality level measurement solutions, get in touch with Aranka Instruments LLP. We are a leading manufacturer and supplier of level transmitters and a wide range of industrial instruments. With our deep expertise in automation and turnkey industrial solutions, we provide the reliability your business deserves. We invite you to explore our products and learn how we can support your next project by visiting: https://arankainstruments.com