V Cone Flow Meter Manufacturer in Ahmedabad, Gujarat

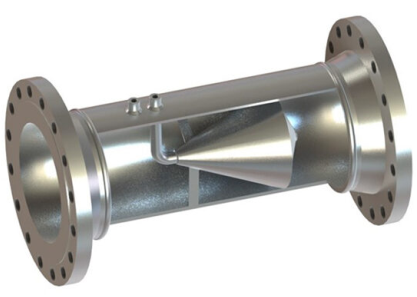

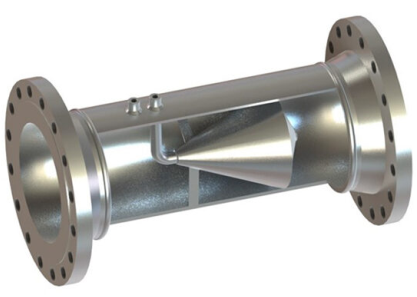

As a leading V Cone Flow Meter Manufacturer and Supplier in Ahmedabad, Aranka Instruments LLP provides advanced differential pressure–based flow measurement solutions designed for accuracy and reliability. The V-Cone Flow Meter operates on Bernoulli’s theorem, which states that as the velocity of a fluid increases, its pressure decreases.

For example, when water enters the V-Cone meter with an initial upstream pressure of P1 = 6 bar, it accelerates as it passes through the cone’s constricted section, where the pressure drops to P2 = 4 bar. This pressure difference (ΔP = 2 bar) is sensed by differential pressure transducers and converted into a corresponding flow rate. The greater the flow velocity, the higher the ΔP value generated. This principle allows the V-Cone meter to deliver precise, repeatable measurements even in turbulent or distorted flow conditions.

Compact in design, self-conditioning, and suitable for liquids, gases, and steam, the V-Cone Flow Meter offers high accuracy, low pressure loss, and minimal maintenance, making it ideal for industrial, chemical, oil & gas, and water process applications.

Product features of V cone flowmeter:

1. It has good accuracy (≤0.5%) and repeatability (≤0.1%).

2. It has a wide range ratio (10:1~15:1)

3. Self-rectifying function, only a very short straight pipe section is needed (1~3D before 0~1D).

4. Self-cleaning function, which can detect dirty and easily fouling fluids, suitable for medium with more impurities such as blast furnace gas.

5. Self-protection function, the key parts of throttling parts are not worn out, and they can keep working stably for a long time.

6. High temperature, high pressure, corrosion resistance, not afraid of vibration.

7. The types of measurable fluids are very wide (liquid, gas, steam), the flow measurement range is wide (small flow to large flow), and the applicable pipelines are DN15 to DN3000.

8. The flow meter structure design is a fluid sweep type structure, it is impossible to intercept any entrained gas, liquid or solid phase dirt in the fluid. It is very suitable for flow measurement of dirty fluids, such as coke oven gas, wet gas, etc.

9. No moving parts

10. When the fluid flows through the filled inner cone, it will form a boundary layer around its periphery and channel the fluid away from the edge of the cone’s tail, thereby reducing the possibility of it being worn.

11. Measure steam and hot water at the heat exchange station, without straight pipe section. Due to the relatively small space of the heat exchange station, the selection of general flow meters requires a long straight pipe section, which affects the operation accuracy. It is used to measure blast furnace gas. It has a self-cleaning effect and the pressure pipe is not easy to be blocked.

| Body material | S.S.304, S.S.316 | |

| Accuracy | ±0.5% of rate (certain fluids and Reynolds number applications require specific calibrations to achieve this value) | |

| Configurations | Precision flow tube and wafer-type | |

| Fitting Type | Flanged, threaded, Others on request | |

| Process Media | Liquid or Gas | |

| Line size | 25 ~ 300 mm | |

| Head Loss | Varies with beta ratio and DP | |

| Installation Requirement | Typically 0-3 diameters upstream and 0-1 diameters downstream of the cone are required, depending on fittings or valves in the adjacent pipeline. | |

| Pressure Range | up to 20 bar [Customize Option Available] | |

| Electronics | Direct Mount or Remote Mount | |

| Standard Beta Ratio | 0.45 to 0.80 | |

| Display | LCD | |

| Power | 24VDC /230VAC | |

| Output | 4 – 20mA, RS485 Modbus RTU [ Optional ] | |

| Temperature Range | Up to 350’C | |

As per Application

• Oil and Gas

• Chemical Manufacturing

• Agriculture and Irrigation

• Food and Beverage

• Plastics

• Pharmaceuticals

• Textiles

• District HVAC

• Metals and Mining

• Process and Industrial app

• Power

• Water and Wastewater

• And More

Frequently Asked Questions (FAQs)

What is a V-Cone Flow Meter?

A V-Cone Flow Meter is a differential pressure (DP) flow measurement device that uses a cone-shaped element to create a pressure differential proportional to the flow velocity in a closed pipe.

How does a V-Cone Flow Meter work?

It works on Bernoulli’s principle, which states that as the fluid velocity increases, pressure decreases. The cone in the pipe causes a flow constriction, creating measurable pressure differences (P1 and P2) used to calculate flow rate.

What are P1 and P2 in a V-Cone Flow Meter?

P1 is the upstream static pressure before the cone, and P2 is the downstream static pressure after the cone. The differential pressure (ΔP = P1 – P2) determines the flow rate.

What is meant by ΔP in flow measurement?

ΔP stands for Differential Pressure, the pressure difference between two points (P1 and P2) that helps determine flow velocity and volume.

What types of fluids can it measure?

It can measure liquids, gases, and steam — including water, air, natural gas, crude oil, and process chemicals.

How does a V-Cone differ from an orifice plate flow meter?

Unlike orifice plates that require long straight pipe lengths, the V-Cone flow meter conditions the flow internally, providing stable readings with minimal installation space.

Does the V-Cone Flow Meter require calibration?

Yes, like other differential pressure devices, it should be factory-calibrated and periodically verified to maintain accuracy.

Can V-Cone Flow Meters handle dirty or multi-phase flow?

Yes, the V-Cone design is self-cleaning and provides accurate results even in fluids containing particulates, bubbles, or multi-phase mixtures.