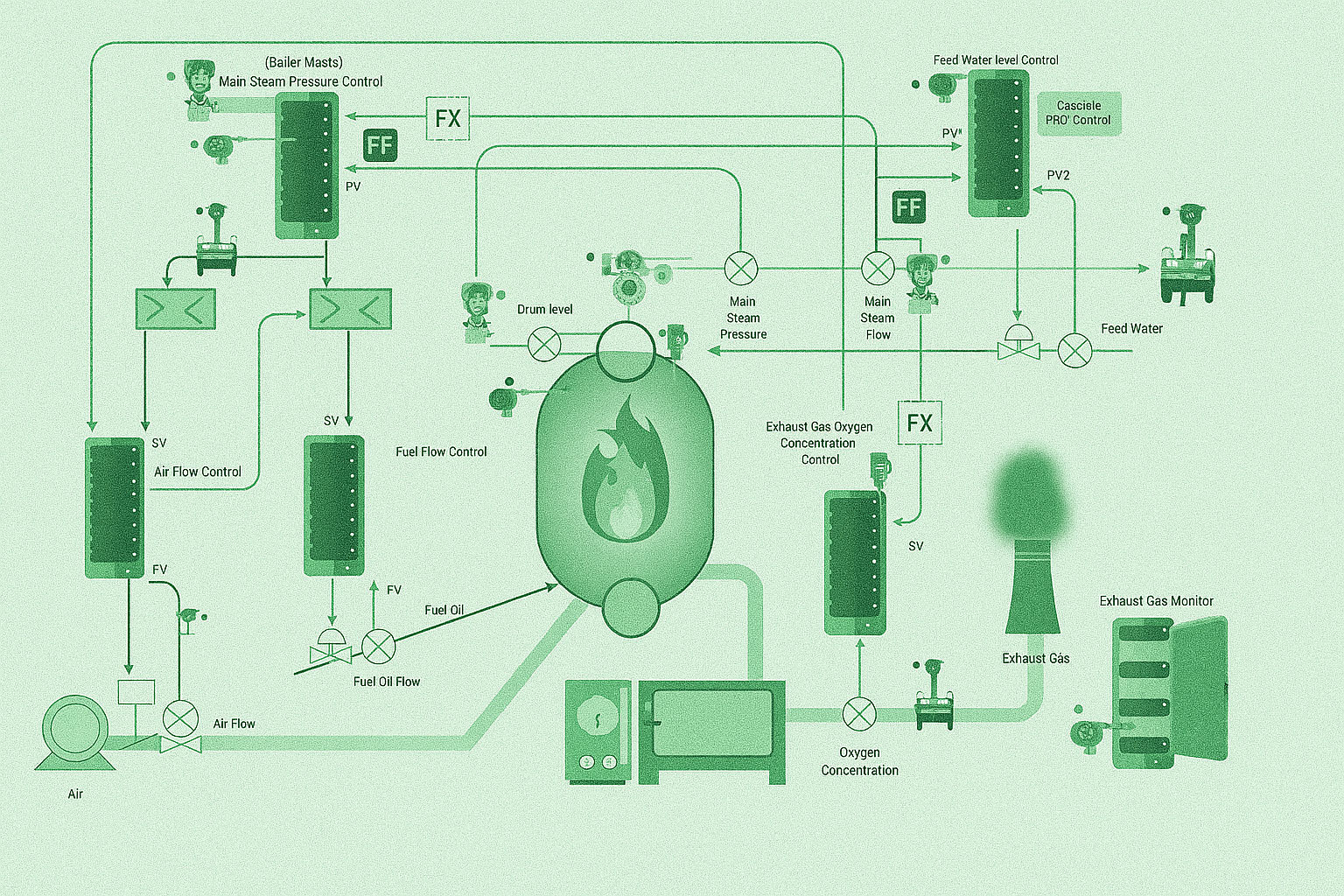

A closed vessel used to heat water or another fluid is called a boiler. A balance between mass and energy is indicated by the boiler control system. Boilers are employed in many different industrial sectors, including paper & pulp, chemicals, electric power, pharmaceuticals, and ceramics. Numerous factors, including growing energy costs, stricter environmental restrictions, growing awareness, and the need for safe, stable, and high-efficiency operation, as well as low emission operation, are influencing the rise of boilers in the majority of industries. Boiler control reduces the process plant’s extra air, blow-down, and steam pressure.

Drum Level Measurement

Process industries make extensive use of drum level measurement systems, and utilities that regulate the boiling water level in boiler drums on process facilities also supply a steady stream of steam. The level of the disturbances, level change, increase or decrease of steam, and feed water flow changes are all managed by a drum level control system.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Feed Water Level Control

The water level in the boiler drum is regularly maintained by a feed water control system, which also modifies the feed water and steam flow. It offers a mass accounting system for the boiler’s feed water and steam leading. Single element, two element, and three element feed water control systems are the three variations of the feed water control system.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Stem Flow Measurement

The two primary categories of steam distribution are statured and super-heated steam. An inadequate supply of steam results in an improper process operation. As a result, steam measurement in process instrumentation requires continuous flow measurement and suitable boiler controls. Superior efficiency in steam measurement is offered by the entire line of flow metering and monitoring solutions from Aranka Instrumentation LLP

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Combustion Control

A closed vessel used to heat water or another fluid is called a boiler. A balance between mass and energy is indicated by the boiler control system. Boilers are employed in many different industrial sectors, including paper & pulp, chemicals, electric power, pharmaceuticals, and ceramics. Numerous factors, including growing energy costs, stricter environmental requirements, growing awareness, and the necessity for safe, stable, and high-efficiency operations, are influencing the expansion of boilers in the majority of businesses. Boiler control reduces the process plant’s extra air, blow-down, and steam pressure.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Exhaust Gas Analysis

The two primary categories of steam distribution are statured and super-heated steam. An inadequate supply of steam results in an improper process operation. As a result, steam measurement in process instrumentation requires continuous flow measurement and suitable boiler controls. Superior efficiency in steam measurement is offered by the entire line of flow metering and monitoring solutions from Aranka Instrumentation LLP.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement