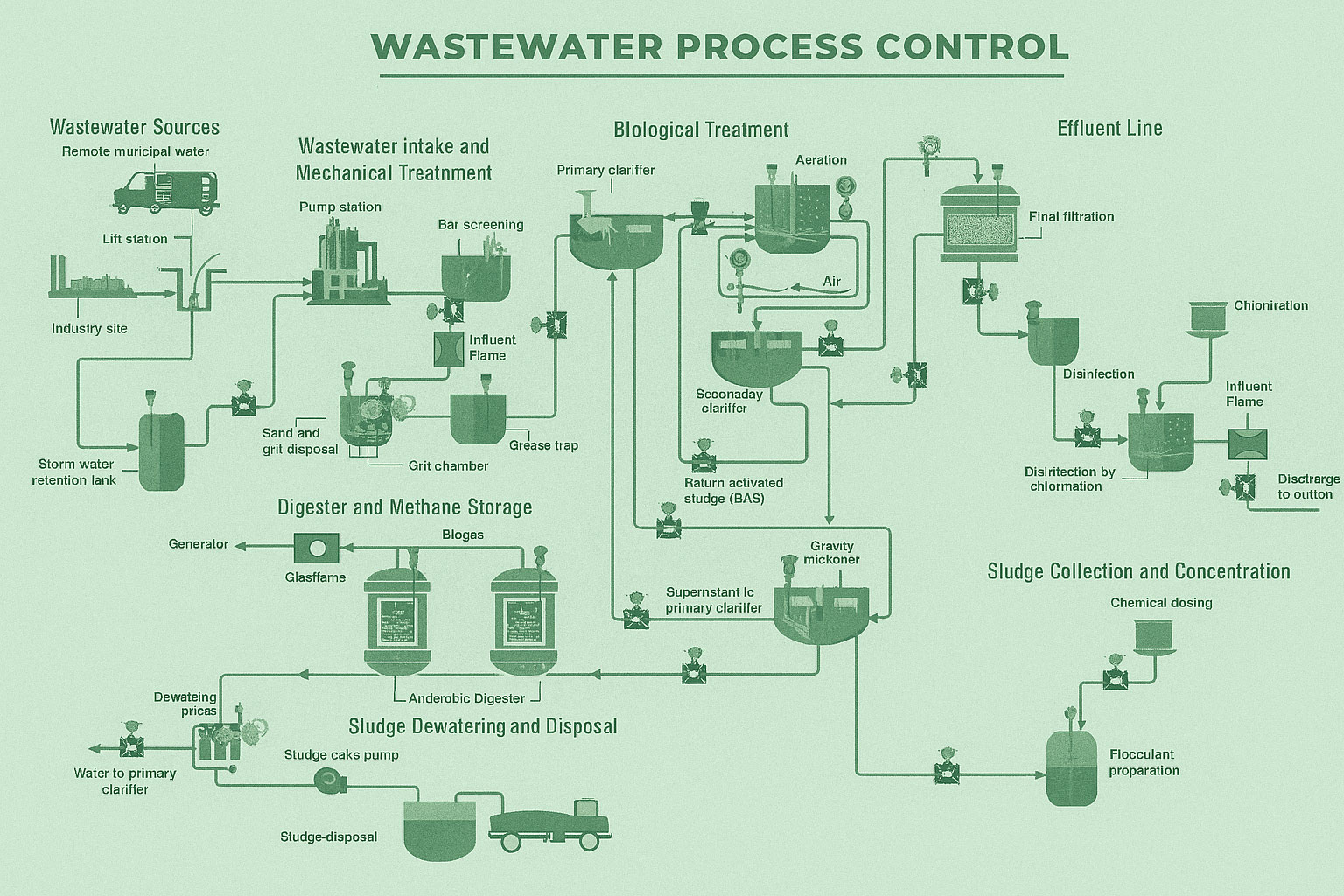

Efficient monitoring and control are essential in wastewater treatment to ensure safe and sustainable water management. ARANKA INSTRUMENTS LLP provides advanced, cost-effective solutions tailored to wastewater treatment plants. Our reliable flow, level, and pressure instrumentation enable precise measurement at every stage, enhancing productivity and operational safety.

Wastewater Intake & Mechanical Treatment

The preliminary stage (primary treatment) focuses on removing large solids that could damage pumps or interfere with downstream processes. Stainless steel bar screens trap debris, while pumps maintain flow and pressure for further treatment.

- Pressure Measurement

- Level Measurement

- Flow Measurement

Biological Treatment (Secondary Treatment)

This stage breaks down organic matter using aerobic and anaerobic processes. Aerobic bacteria convert organic waste into stable inorganic solids, while anaerobic digestion handles more resistant materials.

- Flow Measurement

- Air Flow Control

- Pressure Measurement

- Level Measurement

Effluent Line & Disinfection

Here, remaining suspended solids and pathogens are removed to produce clean effluent. Filtration systems and disinfection units ensure water quality meets environmental standards.

- Pressure Measurement

- Level Measurement

- Flow Measurement

Sludge Collection & Stabilization

Waste Activated Sludge (WAS) from secondary treatment is combined with primary sludge for stabilization. Anaerobic digesters operate at 90–95°F, converting organic matter into methane (CH₄) and carbon dioxide (CO₂), significantly reducing pathogen levels.

- Flow Measurement

- Level Measurement

Sludge Dewatering & Disposal

Centrifuges and dewatering filter presses reduce the liquid content of sludge, producing biosolids with significantly lower weight and volume for disposal.

- Flow Measurement

- Level Measurement

Why ARANKA INSTRUMENTS LLP?

Our wastewater solutions offer:

✅ Accurate and reliable flow, level, and pressure monitoring

✅ Improved operational efficiency and plant performance

✅ Reduced environmental impact through optimized processes

✅ Easy integration and low-maintenance designs