Steel production involves complex processes with critical challenges in maintaining measurement accuracy, operational reliability, and asset uptime. Safety and productivity remain top priorities for plant operators.

At ARANKA INSTRUMENTS LLP, we deliver robust and reliable measurement solutions designed to meet the demanding requirements of the steel industry. Our advanced instruments support every stage—from raw material handling to casting—ensuring improved quality, increased plant uptime, and safe, sustainable operations.

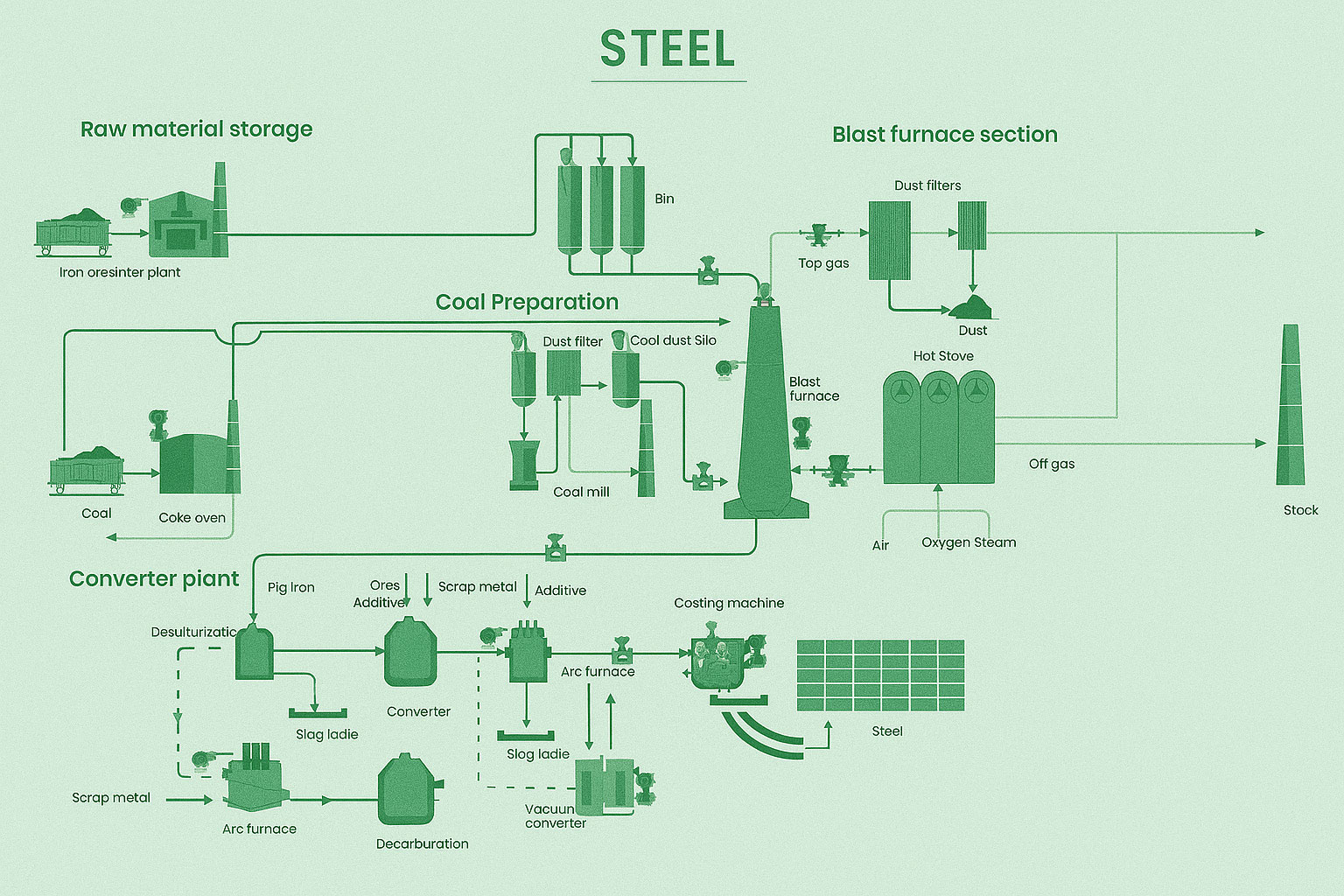

Raw Material Storage & Coke Preparation

Iron ore, coal, and limestone are transported and stored in large silos. Accurate level monitoring of these silos ensures uninterrupted production.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Coke Plant Operations

Coal is stored in silos up to 50m tall and transferred for heating in the absence of air to produce coke. The process involves precise control of temperature (1,000–1,300°C) and gas management.

- Pressure Measurement

- Level Measurement

- Flow Measurement

Blast Furnace Process

The blast furnace combines sinter, coke, and flux materials to produce molten iron. Auxiliary fuels like natural gas and coal are also injected.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Converter Plant & Secondary Metallurgy

In the converter, molten iron is transformed into steel by oxidizing impurities. Secondary processes in ladle furnaces further refine the steel as per customer specifications.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Why Choose ARANKA INSTRUMENTS LLP?

✔️ High-precision flow, level, temperature, and pressure monitoring

✔️ Durable, explosion-proof designs for harsh environments

✔️ Reduced downtime with robust instrumentation

✔️ Cost-effective solutions improving operational efficiency