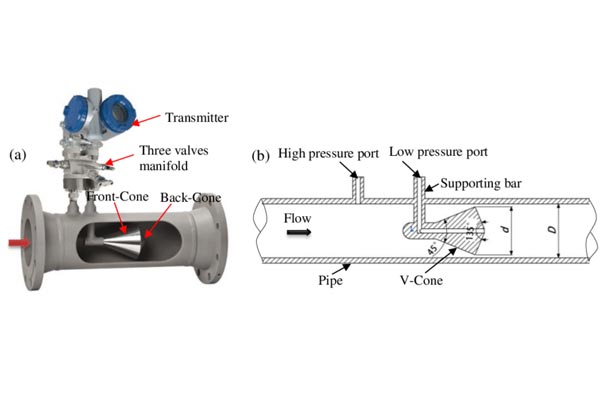

Cone flow meters operate on Bernoulli’s principle, using differential pressure to determine flow rates. As fluid enters the meter, a cone positioned at the center reduces the cross-sectional area, accelerating the flow and creating a pressure drop. The upstream pressure (P1) and downstream pressure (P2) are measured using differential pressure transducers, allowing the flow rate to be calculated based on the conservation of mass and energy.

This design creates a low-pressure zone downstream and induces controlled turbulence, stabilizing the flow profile for accurate measurement. The cone also reduces wear and extends meter life, making it ideal for high-velocity and abrasive flows.

Flow calculation and beta ratio

The beta ratio for a cone flow meter is defined as:

Beta ratio = [(D² – d²)^0.5] / D

Where:

-

D = pipe’s internal diameter

-

d = cone diameter

This unique geometry allows beta ratios above 0.75, ensuring superior performance in challenging environments. Cone flow meters are highly repeatable, require minimal maintenance, and support a wide range of flow applications.