Whether your end product is cream, butter, milk powder, cheese, or simply milk, Aranka Instrumentation delivers innovative solutions to help you produce it efficiently, reliably, and hygienically. Our products are designed for safe operation, easy maintenance, and long-term cost savings—ensuring maximum productivity.

Milk Intake & Storage

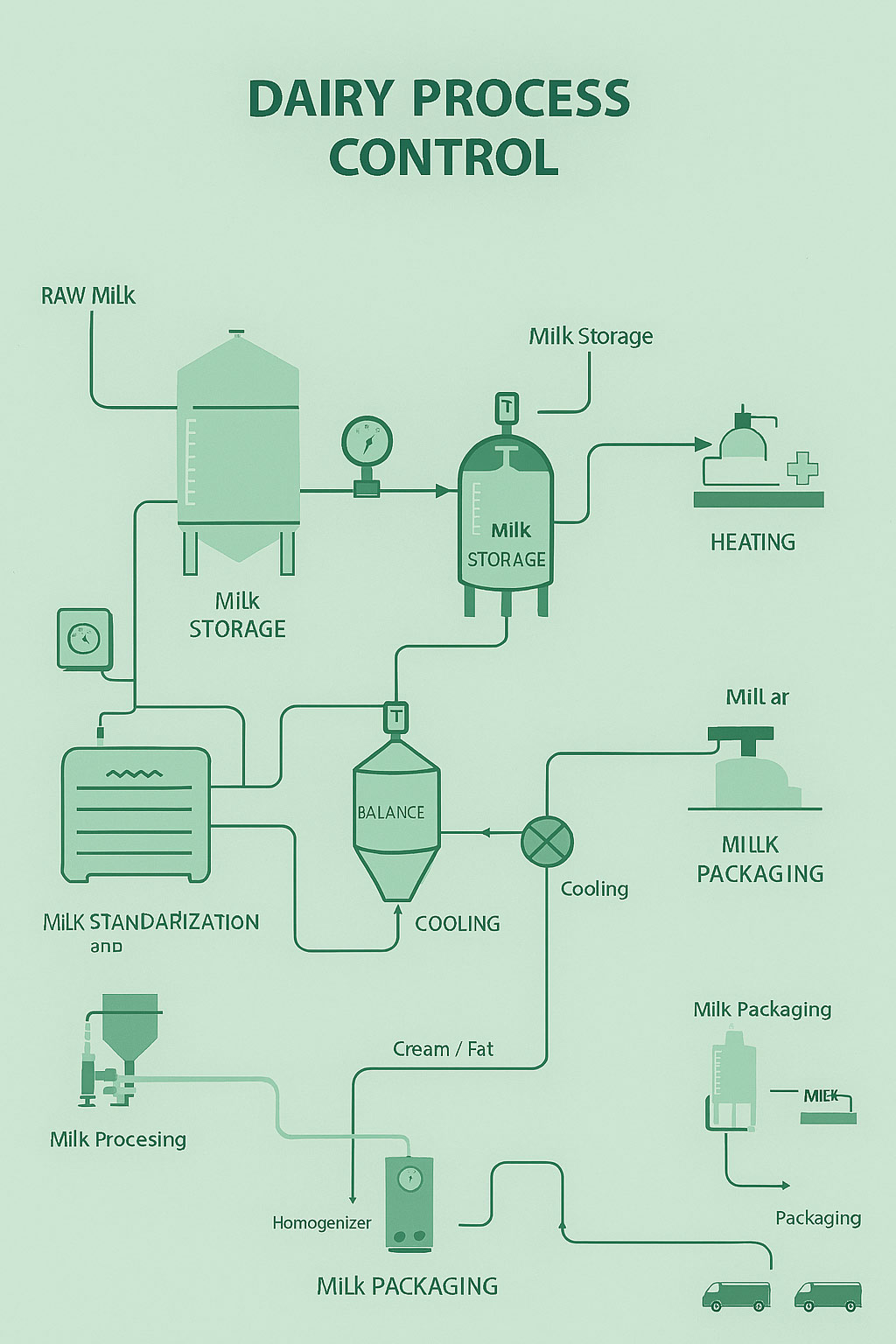

Milk received from tankers is stored in the tank farm at around 39°F (4°C) and kept under constant agitation to maintain uniform temperature and prevent milkfat separation. Approved milk is then pumped into silos for pasteurization, homogenization, separation, and further processing.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Milk Heating & Pasteurization

Pasteurization involves heating milk to a specific temperature for a set holding time and then cooling it rapidly to eliminate harmful microorganisms. Homogenization follows, pushing milk through atomizers to evenly distribute fat particles for a smooth, consistent texture.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Milk Powder Production

Milk powder production removes water content using vacuum boiling or low-pressure, low-temperature evaporation. The concentrated milk is then spray-dried into a fine mist of hot air, transforming it into powder form.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Cheese Production

Starter cultures and rennet are added to initiate fermentation, determining cheese flavor and texture. The curd forms and releases whey during syneresis, after which it is pre-pressed into a cheese “cake” and residual whey is drained.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

Why Choose Aranka for Dairy?

- Hygienic and contamination-free operations

- Precision monitoring across all dairy processes

- Easy integration and maintenance

- Increased efficiency and cost savings