Although mining is vital to the world economy, it faces several difficulties, including unfavourable working conditions and environmental effects. In order to maintain a balanced and optimal mineral processing operation, Tektrol offers flow monitoring solutions that can help optimise mining operations, boost productivity, and cut expenses. Mining firms can meet safety regulations, boost plant uptime, increase cost-effectiveness, and maximise product yield with Tektrol’s solutions.

Excavation

In mining, excavation is a crucial multi-stage operation that needs to be carefully planned for in order to protect workers and reduce environmental damage. Although the process requires large expenditures in infrastructure, labour, and equipment, production can be maximised and expenses can be decreased with the use of cutting-edge monitoring technology. Protability depends on effective excavation management, and environmental impact must be minimised through sustainable procedures. The excavation process can be completed safely, effectively, and sustainably by implementing cutting-edge technologies and best practices.

- Level Measurement

Transportation

In mining, transport procedures are essential, and precise measurement is required to guarantee effectiveness and seamless operations. While mass flow monitoring on conveyor belts is necessary to track the quantity of material being moved, level measurement is essential in torpedo cars and the sintering plant. Mining operations may maximise output, decrease downtime, and minimise costs by utilising sophisticated measurement technologies.

- Level Measurement

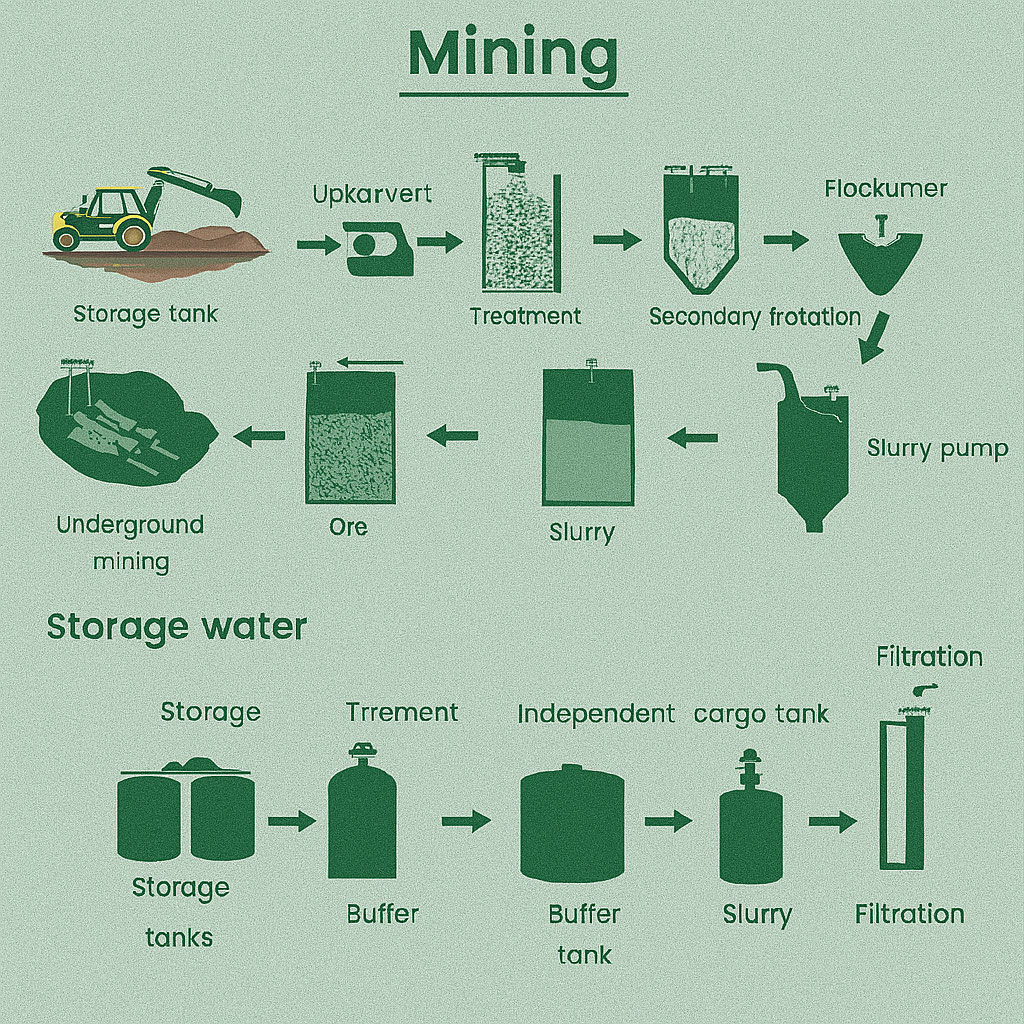

Storage

Storage tanks and silos are essential to the mining process for raw materials, intermediate products, and finished goods. Accurate and dependable point level detection and level measuring devices are necessary to guarantee the safe and effective handling of goods. Maintaining the processing pressure of some materials also depends on measuring the pressure in buffer tanks. To stop leaks and guarantee safe handling, toxic liquid storage tanks need to have accurate level measuring and point level detection. On the other hand, precise level measurement is necessary to operate top-notch equipment in the coolant tank. All things considered, the mining requires a thorough strategy to handling and storage, including trustworthy point-level detection and level monitoring equipment.

- Level Measurement

Grinding

In mining, grinding is a procedure that shrinks the area for processing later on. The ore is crushed into smaller pieces by large spinning mills that include steel balls or rods. SAG and ball mills are used in the initial and secondary grinding stages of the process, respectively. For downstream processing to maximise mineral recovery and minimise energy consumption, the grinding process must be as efficient as possible.

- Level Measurement

Production

Level and density readings are crucial to the mining’s safe and effective operations. In many operations, including feeding materials into machines, maintaining correct mixing and preventing overflow, controlling temperature and pressure, preventing dry running and overfilling, and keeping an eye on mineral concentration and efficiency, these measurements are essential.

- Level Measurement