Paper remains an integral part of daily life, serving countless applications from education to packaging. At ARANKA INSTRUMENTS LLP, we provide advanced measurement and control solutions to optimize the paper production process—ensuring efficiency, sustainability, and consistent product quality.

Preparation of Raw Materials

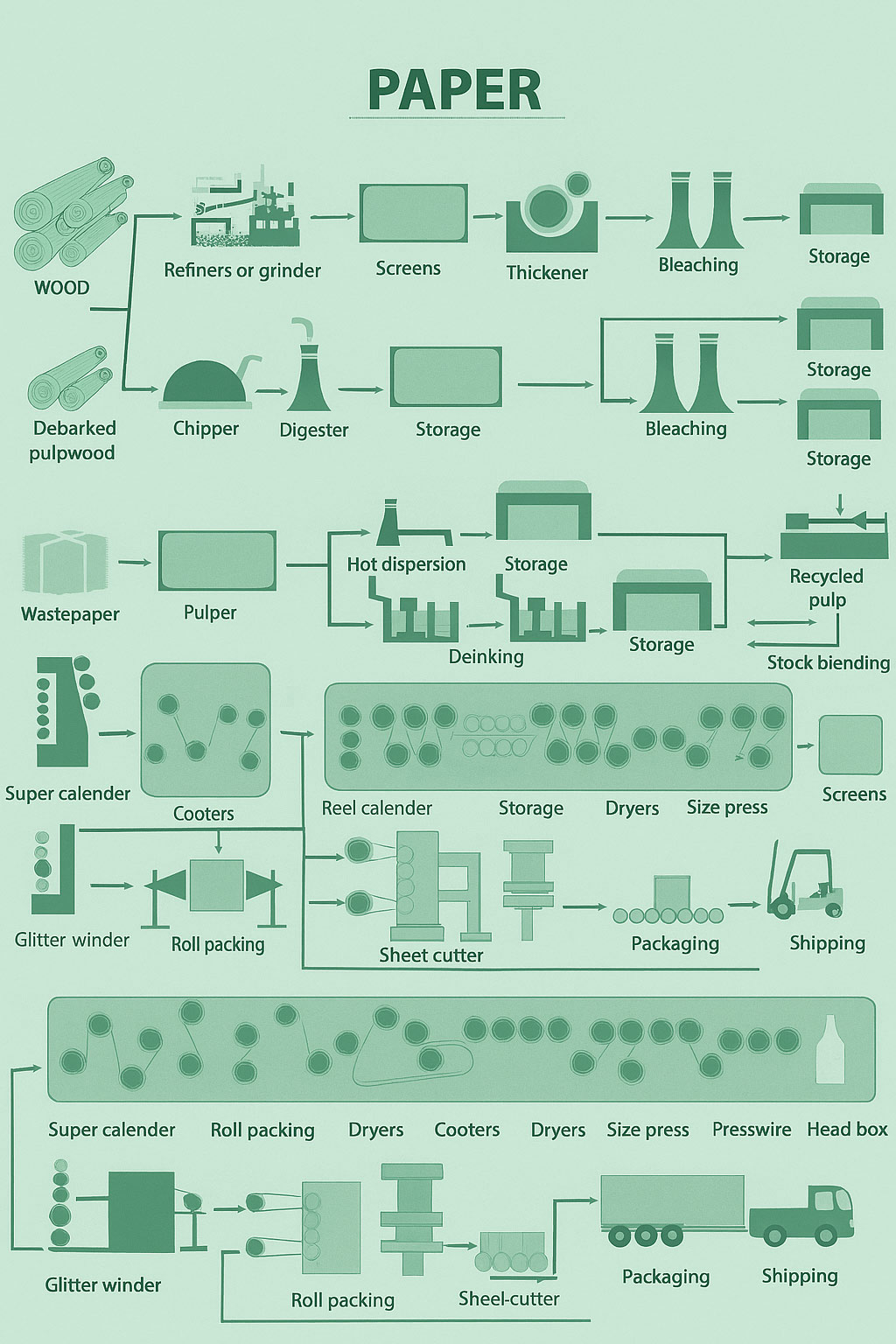

The papermaking journey begins with the preparation of raw materials. Wood received at pulp mills arrives in various forms such as short logs (bolts) or wood chips from sawmills.

-

Debarking: Logs are debarked using large tumbling drums with water sprays.

-

Chipping: Debarked wood is chipped into uniform sizes suitable for pulping.

-

Screening & Cleaning: Chips are screened, cleaned, and stored for further processing.

Fiber Separation

The next step involves separating fibers using mechanical or chemical pulping:

-

Chemical Pulping: Wood chips are cooked with chemicals in large digesters under high pressure and temperature, breaking down lignin to release cellulose fibers.

-

Mechanical Pulping: Logs or chips are ground against rotating stones or refined using thermo-mechanical processes.

-

Post digestion, pulp is washed, screened, and cleaned, removing most process water before papermaking.

Bleaching Process

To achieve the desired brightness and whiteness, pulp undergoes a bleaching process:

-

Chemical Bleaching: Removes remaining lignin using chlorine dioxide, hydrogen peroxide, or oxygen-based agents.

-

Mechanical Bleaching: Targets only coloring impurities to retain high fiber yields, using agents like sodium bisulfite and hydrogen peroxide.

The choice of chemicals depends on pulp type, desired paper quality, and environmental considerations.

Papermaking Process

Refined pulp is diluted to a thin slurry and cleaned for papermaking:

-

Headbox Distribution: The slurry is evenly spread onto a moving screen.

-

Water Removal: Water drains through the screen, forming a continuous fiber mat.

-

Pressing: The fiber mat is pressed to enhance density and remove water.

-

Drying: Heated cylinders evaporate remaining moisture, producing dry paper sheets.

-

Finishing: The paper is smoothed and treated for various applications.

Why Choose ARANKA INSTRUMENTS LLP?

Our advanced solutions for the pulp & paper industry deliver:

✔️ Accurate flow, pressure, level, and temperature monitoring

✔️ Optimized production efficiency

✔️ Sustainable processes with reduced environmental impact

✔️ Reliable operation and easy maintenance