Capacitance Level Switch Manufacturer

As a leading Capacitance Level Switch Manufacturer in Ahmedabad, Aranka Instruments LLP offers precision-engineered point-level sensors that work on the capacitance principle. Two electrodes — the detection probe and the ground reference — act like parallel plates, and the capacitance (C) varies based on the plate area (S), distance (L), and the dielectric constant (ε) of the material between them.

The Aranka Capacitance Level Switch operates on the principle of dielectric variation. When the probe is in air, the capacitance remains low (dielectric ≈ 1.0). As liquid or solid material surrounds the probe, the dielectric constant increases (≈ 2–5), which raises the capacitance. The electronics sense this change and generate a precise ON/OFF output for pumps, alarms, or level control. This reliable principle allows accurate detection of conductive and non-conductive liquids, slurries, and powders, ensuring stable performance in diverse industrial applications.

- Capacitance Measurement: They operate by detecting the change in capacitance between a probe and the container wall, which varies with the level of the material.

- Versatile Liquid Compatibility : This level switch is compatible with a wide range of liquids, including water, oil, chemicals, slurries, and other conductive or non-conductive fluids. It is suitable for various industries such as oil and gas, food and beverage, pharmaceuticals, wastewater treatment, and many more.

- High Accuracy and Sensitivity : The Capacitance Level Switch offers high accuracy and sensitivity in detecting liquid levels. It can detect small changes in liquid levels, ensuring precise monitoring and control. This accuracy is crucial for maintaining process efficiency, preventing spills, and optimizing operations.

- Adjustable Sensitivity and Calibration : The switch allows for easy adjustment of sensitivity and calibration to accommodate different liquid properties and application requirements. This flexibility ensures optimal performance and adaptability to various liquid types, densities, and temperatures.

- Multiple Probe Options : The Capacitance Level Switch is available with various probe options to suit different installation needs. You can choose from flexible or rigid probes, depending on the tank or vessel configuration. The probes can be inserted directly into the liquid or mounted externally for non-intrusive measurements.

- Easy Installation and Integration : The switch is designed for easy installation and integration into existing systems. It can be mounted on tanks, vessels, or pipelines using standard fittings, making it convenient to incorporate into industrial processes without significant modifications.

- Output Options : The Capacitance Level Switch offers a range of output options to interface with control systems or alarms. It can provide simple on/off signals, analog signals, or digital communication protocols, allowing seamless integration into existing process control infrastructure.

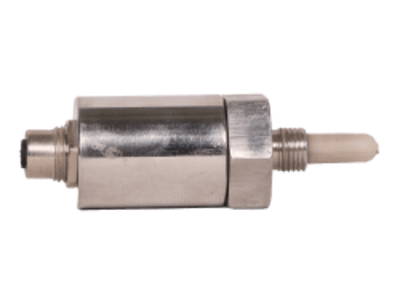

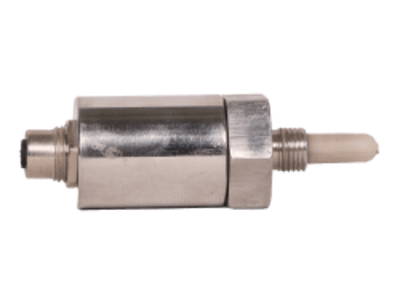

- Robust Construction : Built to withstand demanding industrial environments, this level switch features a robust construction. It is designed to withstand harsh conditions such as high temperatures, pressure, and corrosive substances. The switch is made from durable materials such as stainless steel or corrosion-resistant alloys, ensuring long-lasting performance and reliability.

- Easy Maintenance : The Capacitance Level Switch requires minimal maintenance due to its non-contact operation and durable construction. Routine cleaning and inspection are straightforward, and the absence of moving parts reduces the need for frequent replacements or repairs.

| Power | 24VDC | |

| Sensing | Any Conductive or Non Conductive Liquide, Powder | |

| Output | Transistor output or Relay output | |

| Connection | Thread, Flange, Try Clamp | |

| Sensing MOC | PTFE & SS 316, Optional Customized | |

| Operating Temperature | 0 ~ 70’C, Customized Possible | |

| Operating Pressure | 0~15 Bar | |

As per Application.

Any Conductive or Non Conductive Liquid, Powder Sensing.

Frequently Asked Questions (FAQs)

What is a Capacitance Level Switch?

It’s a point-level device that detects the presence/absence of material by measuring capacitance changes between a probe electrode and a ground/reference.

How does it differ from a Conductivity Level Switch?

Conductivity switches require conductive liquids to complete a circuit. Capacitance works with both conductive and non-conductive media, including powders and oils.

Can it detect powders and granular solids?

Yes. Changes in dielectric from air → solid cause a measurable capacitance shift, enabling reliable high/low level trips in silos and hoppers.

What about coating or buildup on the probe?

Models with insulated probes, guard electrodes, and coating compensation minimize false trips. Periodic cleaning is recommended for heavy build-up services.

What outputs are available?

Standard is relay SPDT (CO). Options include PNP/NPN transistor outputs and supervisory 4–20 mA (model-dependent).

Can it be used in high temperature/pressure?

Yes—choose the high-temp/high-pressure probe build (appropriate seals/insulation) within the specified limits.