Float Level Switch Manufacturer & Supplier in Ahmedabad

Aranka Instruments LLP is a trusted Float Level Switch Manufacturer & Supplier in Ahmedabad, delivering reliable, accurate, and cost-effective liquid level sensing solutions for industrial applications. Our Float Level Switches operate on the principle of buoyancy, where the float rises and falls with the liquid level and actuates a micro switch or magnetic reed switch to indicate high or low level conditions. This enables automatic pump control, alarm activation, and protection against overflow and dry-run conditions in tanks, sumps, and reservoirs.

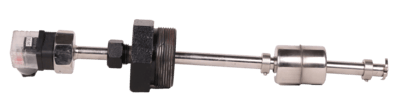

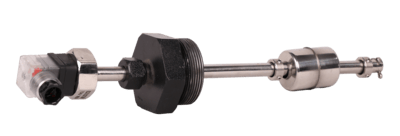

Each float level switch is designed for rugged industrial performance and ease of installation. Available in SS304 / SS316 stainless steel, polypropylene (PP), or PVC construction, our float switches can operate at temperatures up to 120 °C and pressures up to 10 bar. They support multiple mounting options, top, side, or bottom entry, and are compatible with PLCs, control panels, and automation systems. As a reliable Float Level Switch Supplier in Ahmedabad, we supply standard and customized models suitable for water, chemicals, acids, oils, and other industrial liquids. With proven engineering and quality manufacturing in Ahmedabad, we ensure every float level switch delivers long service life, precise switching, and stable performance in harsh industrial environments.

A Float Level Switch is a contact-type liquid level sensor that uses a buoyant float mechanism to open or close an electrical circuit at predefined liquid levels. These switches are widely used to control pumps, valves, and alarms when liquid levels rise or fall to specific points in industrial tanks, sumps, and vessels. Float switches are available in two main types: Magnetic (reed switch type) and Mechanical float type.

Key advantages of our industrial float level switches include:

- Simple & low-cost mounting.

- Doesn’t require an auxiliary power supply.

- It can be used for any kind of liquids like Acids, Chemicals, etc.

- Potential-free and switching voltage up to 230V.

- Surface disturbances like bubbling, foaming, and ripples will not affect its performance.

- It can be used with a temperature sensor or temperature switch.

- The fluid conductivity & Dielectric constant will not affect operation.

| Sensor Output | 3A to 10A Potential Free Contact | |

| Sensing Output Nos. | 1 Nos. to 4 Nos. | |

| Connection | Thread, Flange, Try Clamp | |

| Sensor MOC | SS304, SS316, PP, PTFE | |

| Sensor Mounting | Top / Side Mount | |

| Operating Temperature | up to 120°C | |

As Per Application.

- This switch is used to turn ON and OFF a pump or open or close an electronic valve.

- This switch activates tank level alarms to protect & inform of a possible hazardous spill.

- This switch is used to protect heaters and also other equipment from severe injuries and dangerous situations.

- This switch is very helpful in monitoring the level of liquid within different industrial & residential applications and is normally connected to a valve or pump or an alarm to inform a user.

- Industrial washers use these switches for monitoring the washer water level.

- Air conditioning & refrigerant use these switches for controlling the water levels.

- These switches are used in the beverage industry for filling or emptying the beverage tanks.

- Water tank float switches can help in water level control for potable water, rainwater, wastewater, and sewage application. This pump switches on/off with the rise/fall of the float switch in the water.

- These are used in sump pumps & sewage pits can sense and activate a pump to avoid increasing water levels.

Frequently Asked Questions (FAQs)

What is a Float Level Switch?

A float level switch is a liquid level sensor that uses a buoyant float to open or close an electrical circuit, indicating whether the liquid level is above or below a predefined point.

How does a Float Level Switch work?

It operates on the principle of buoyancy. As the liquid level rises or falls, the float moves accordingly and actuates a switch (mechanical or magnetic) to signal level change.

What are the types of Float Level Switches?

They are mainly classified as mechanical float switches and magnetic (reed or electromagnetic) float switches.

What materials are used for float construction?

Depending on the liquid type, floats are made of SS304, SS316, polypropylene (PP), or PVC for corrosion and chemical resistance.

Where are Float Level Switches used?

They are widely used in water treatment, chemical plants, oil & fuel storage tanks, boilers, and process control systems.

What are the advantages of Float Level Switches?

They are simple, durable, low-maintenance, and can operate in both clean and contaminated liquids, providing reliable level control.

Can the mounting orientation be customized?

Yes, we offer top, side, or bottom mounting configurations to suit various tank designs and space constraints.

What temperature and pressure can they handle?

Our float level switches are designed to operate at temperatures up to 120 °C and pressures up to 10 bar, depending on material and model.