India’s sugar industry depends heavily on sugarcane—a bulky, low-value, perishable raw material. Efficient processing is critical, as sugarcane cannot be stored long due to sucrose loss and is not suitable for long-distance transport. With raw material costs contributing nearly 50% to production, precision and efficiency at every stage are key.

At ARANKA INSTRUMENTS LLP, we offer advanced solutions for accurate measurement and process control across the entire sugar production chain—from beet receiving to crystallizatio

Sugar Beet Sowing & Harvest

Sugar beet is sown in spring and harvested after about 180 days of sunlight. Post-harvest, beets are temporarily stored in field clamps before being transported to processing plants.

Beet Receiving & Extraction

Beets arrive at the plant’s beet yard via lorries and are conveyed to washing stations. Slicer machines cut them into thin strips (cossettes), and diffusion towers use hot water to extract sugar, creating raw juice. Spent beet pulp is repurposed as animal feed.

Juice Purification & Evaporation

Non-sugar components are removed using calcium carbonate and CO₂ during purification. Double filtration produces a pale-yellow clarified juice with ~16% sugar content. In evaporation units, water is removed in stages, concentrating the juice to ~70% sugar for the next phase.

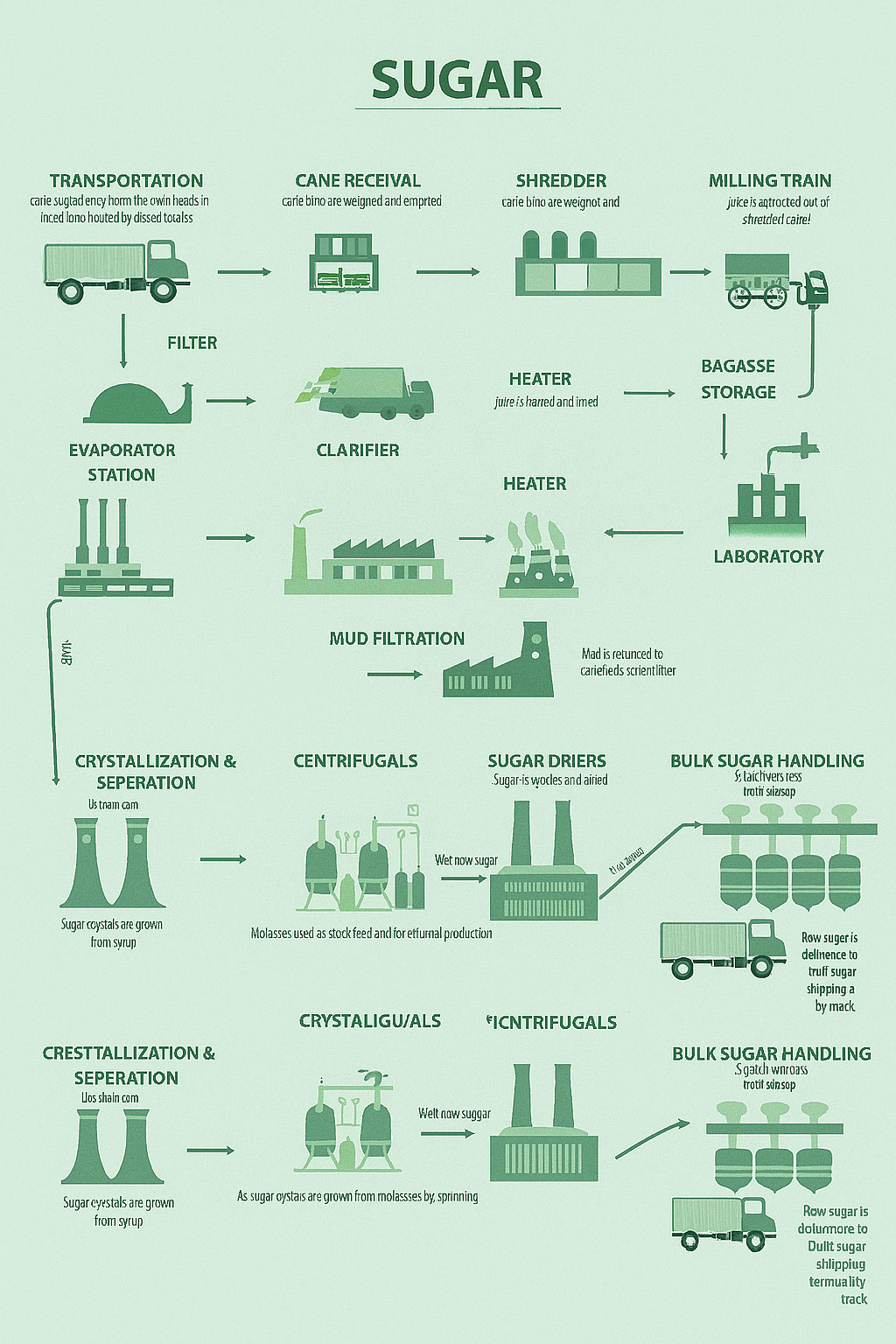

Milling (Sugarcane)

For sugarcane, the shredded sticks pass through a series of three-roller mills (top, feed, and discharge rollers). Poorer juice from later mills is recycled, and hot water is applied in the final milling for maximum extraction efficiency.

Clarification & Filtration

Raw cane juice undergoes clarification in conical vessels where lime, phosphoric acid, and sulfur dioxide help settle impurities. Clean juice rises while sludge settles and is later filtered using rotary vacuum filters to remove residual solids.

Crystallization & Centrifugation

The concentrated juice is boiled to form sugar crystals in a thick syrup (massecuite). This mixture cools in mash tuns before entering centrifuges where crystals are separated from molasses. Refining the crystals yields high-purity sugar, while molasses is used for animal feed, yeast, and alcohol production.

Storage & Packaging

Finished sugar is dried, cooled, and stored in silos. It is then sieved and packaged in various forms to meet market demands, ensuring quality and consistency for consumers.

Why ARANKA INSTRUMENTS LLP?

Our solutions empower sugar plants with:

✔️ Accurate flow, level, and pressure monitoring

✔️ Optimized energy use across processes

✔️ Minimal waste and improved extraction efficiency

✔️ Easy integration with existing systems